HOTLINE:

+86-27-87862117

mobiles

Copyright(C)2023,GA Measurement Control Equipment Co.,Ltd. All Rights Reserved. Supported by Toocle 31fabu Copyright Notice

1.png)

Main process

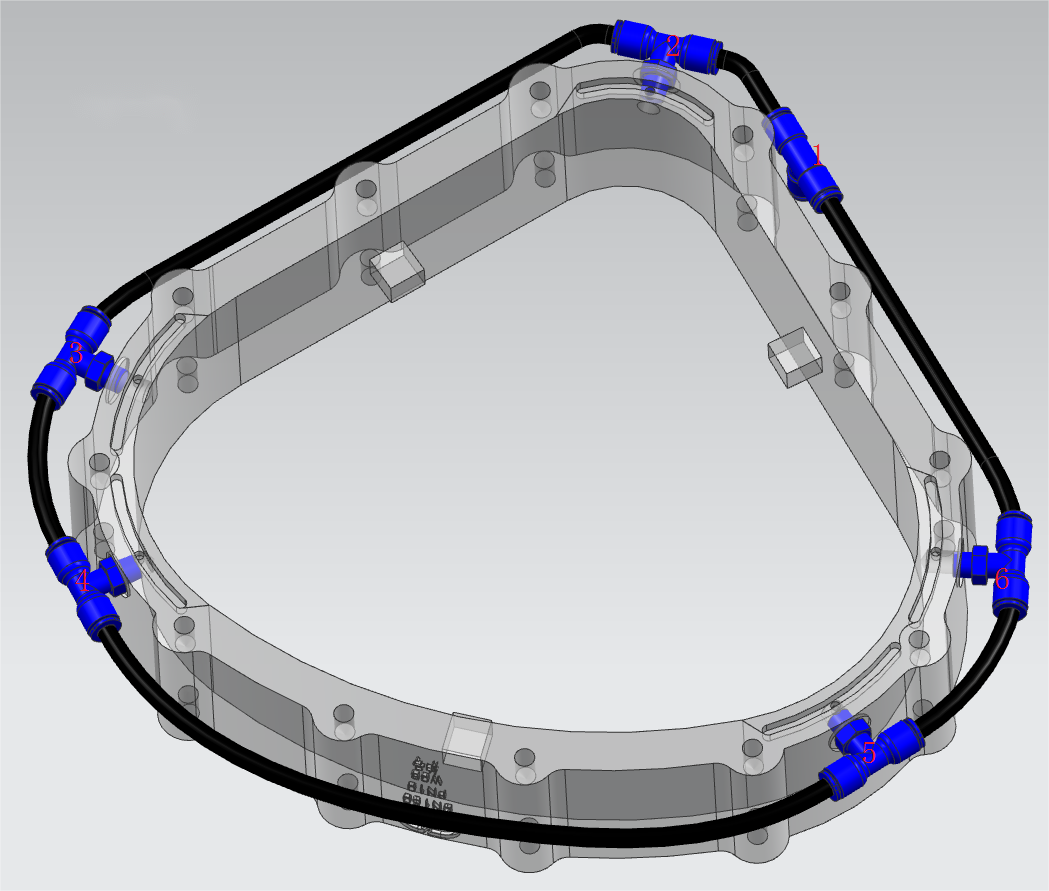

Process air storage slots around the grinding disc valve ring in areas prone to dust accumulation.

片(piàn)2.png)

An L-shaped hole is machined in the middle of the air storage tank to connect to the air intake pipe outside the ring, and the blowing and sweeping flow channel is connected.

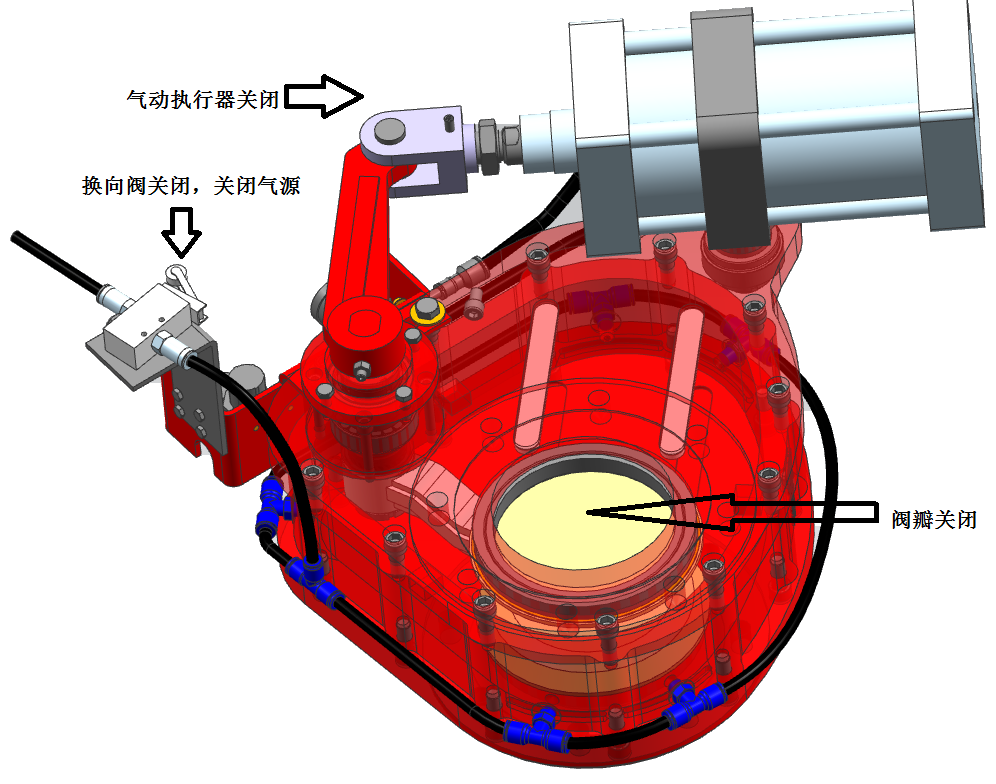

operational principle

When the powder conveying equipment sucks and discharges materials, the pneumatic actuator piston rod extends, driving the connecting rod to trigger the directional valve. Compressed air enters the air storage tank and continuously or intermittently supplies gas to the valve chamber through the blowing port, purging the residual powder medium inside the valve chamber.

After the suction and discharge operation of the powder conveying equipment is completed, the pneumatic actuator piston rod retracts, the valve closes, and the directional valve cuts off the circuit supplying air to the blowing port, and the blowing function automatically stops.